| Diameter of Saw Wheel | 42″ | 48″ |

| Width of Saw wheel | 3 | 3 |

| Trolley Size | 12’x3.5′ 16’x4′ | 12’x3.5 16’x4′ |

| Blade Length | 32 ft | 32 ft |

| Approx Speed of Saw Wheel- RPM | 540 | 540 |

| Power Required | 15hp | 20hp |

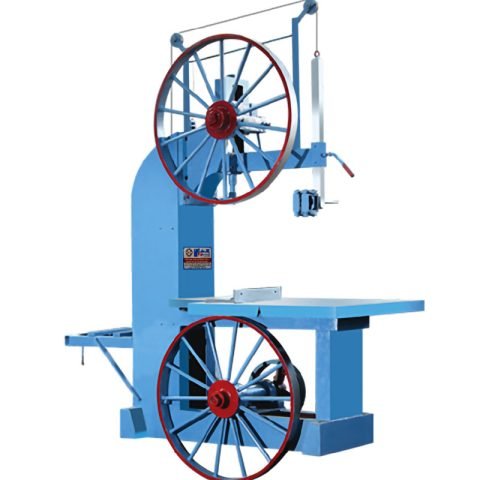

Here are some key features and aspects of a horizontal trolley bandsaw for saw mills:

Frame and Structure

The machine typically consists of a heavy-duty frame and structure that provides stability and support during the cutting process. It is designed to handle large logs and withstand the rigors of sawing.

Bandsaw Blade

The horizontal trolley bandsaw uses a continuous loop bandsaw blade that moves horizontally through the log. The blade is tensioned tightly to ensure accurate and straight cuts.

Trolley System

The trolley system carries and moves the log through the cutting process. It is typically equipped with rollers or other mechanisms to facilitate smooth and controlled movement of the log along the cutting path.

Log Clamps or Dogs

The machine may feature log clamps or dogs that secure the log in place during cutting. These clamps or dogs ensure stability and prevent the log from shifting or moving during the sawing operation.

Blade Guides

The machine is equipped with blade guides that support and guide the movement of the bandsaw blade. The blade guides help maintain proper blade alignment, minimize blade deflection, and ensure smooth cutting performance.

Cutting Capacity

Horizontal trolley bandsaws for saw mills have a significant cutting capacity, allowing for the processing of large logs of various sizes. The maximum cutting capacity is determined by the throat depth, which is the distance between the blade and the frame.

Power and Control

The machine is powered by an electric motor or other power source. It may feature a control panel or system for adjusting the cutting speed, feed rate, and other cutting parameters. This control system allows for customization based on the specific requirements of the logs and lumber being processed.

Safety Features

Horizontal trolley bandsaws for saw mills are equipped with safety features to protect the operator during operation. These can include safety guards, emergency stop buttons, and safety interlocks to prevent access to the blade and other moving parts.

There are no reviews yet.