| Maximum Length for splitting | Max. up to 4′ |

| Maximum Dia for splitting | 200 MM |

| Dimensions of the machine | 6′ x 2′ x 4′ |

| Approx. weight, in kg | 300 KG |

| Power Consumption | 3 H.P. |

| Maximum length for splitting | Max. up to 4′ |

| Maximum Dia for splitting | 200 MM |

| Dimensions of the machine | 8′ x 2′ x 4′ |

| Approx. weight, in kg | 500 KG |

| Power Consumption | 5 H.P. |

| Purpose | in comparison of Hand Splitter |

Here are some key features and aspects of a bamboo chain splitter machine:

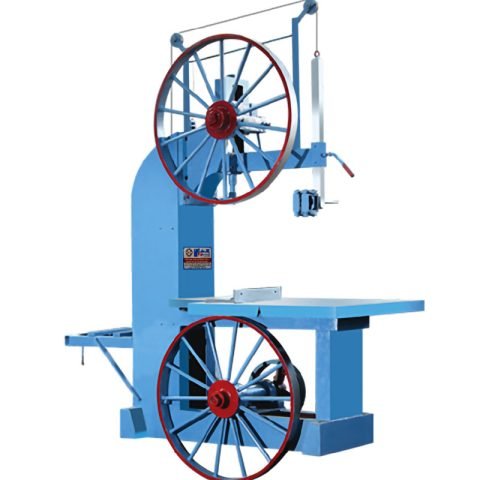

Structure and Design

The machine is designed with a sturdy frame or structure to provide stability and support during the splitting process. It typically consists of a feeding mechanism, splitting blades, and a control system.

Feeding Mechanism

The machine includes a feeding mechanism that allows the bamboo culms to be fed into the machine for splitting. This can be a manual or automated feeding system, depending on the specific machine model.

Splitting Blades

Bamboo chain splitter machines have specialized blades or cutting tools designed to split the bamboo culms into thinner chains or strips. These blades are typically adjustable, allowing for different thicknesses of the split chains.

Control System

The machine may feature a control system that allows the operator to adjust the speed and intensity of the splitting process. This helps in achieving desired results based on the specific requirements of the bamboo strips.

Safety Features

Bamboo chain splitter machines are equipped with safety features to ensure the operator’s safety during operation. These may include safety guards, emergency stop buttons, and safety interlocks to prevent access to moving parts.

Output Conveyor

Some machines may have an output conveyor system that collects the split bamboo strips and moves them away from the cutting area for further processing or collection.

Capacity and Output

The capacity of bamboo chain splitter machines can vary, depending on the specific model and design. The machine’s output or production rate is influenced by factors such as the size and thickness of the bamboo culms and the desired thickness of the split chains.

Maintenance and Upkeep

Proper maintenance and periodic cleaning of the machine are important to ensure its optimal performance and longevity. Regular blade sharpening or replacement may be required to maintain the quality of the split bamboo chains.

There are no reviews yet.