| Description | PCP-50 | PCP-100 |

| Table Size | 1250x2500m | 1250x2500m |

| Max Presure of Workable | 50T | 100T |

| Pressure of Hydraulic System | 210kgs/cm2 | 210kgs/cm2 |

| Max. Platen Opening | 1000mm | 1000mm |

| Oil Cycling Dia | Dia 125mm x 2pcs | Dia 125mm x 2pcs |

| Hydraulic Pump Power | 5.5KW | 5.5KW |

Here are some key features and aspects of a cold press panel processing machine:

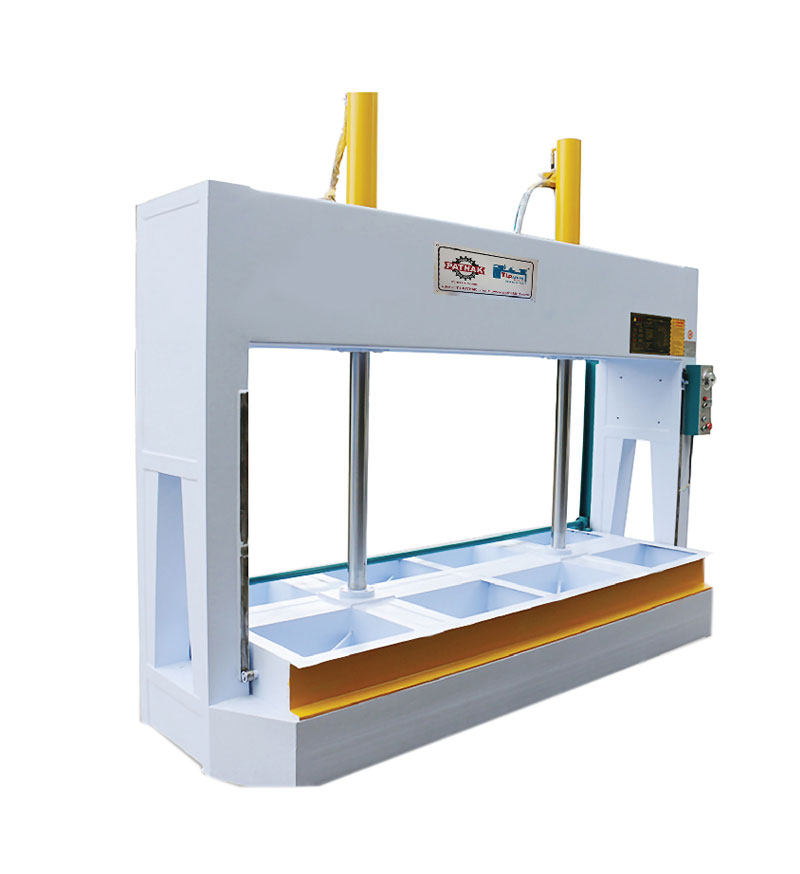

Structure and Design

The machine consists of a sturdy frame or structure that provides stability during the pressing operation. It typically includes a working table or bed where the panels or materials to be laminated are placed.

Pressing Mechanism

The machine utilizes a hydraulic or pneumatic system to apply pressure to the panels or materials. This pressing mechanism ensures even pressure distribution across the entire surface to achieve a strong and uniform bond.

Heat-Free Operation

Unlike a hot press machine that uses heat and temperature to activate adhesives, a cold press machine does not involve heat in the pressing process. It relies solely on pressure to create the bond between the layers of materials.

Pressure Control

Cold press machines usually have a pressure control system that allows the operator to adjust and set the desired pressure level based on the specific requirements of the materials being laminated. This control ensures precise and consistent results.

Adhesive Application

Prior to pressing, adhesive is applied to the surfaces of the materials being laminated. The type of adhesive used depends on the specific application and materials involved. The adhesive can be manually applied or, in some cases, the machine may have an integrated adhesive application system.

Panel Alignment

Cold press machines often include alignment mechanisms or guides to ensure accurate positioning and alignment of the panels or materials during the pressing process. This helps achieve proper bonding and avoids misalignment or shifting.

Timer and Cycle Control

Some machines are equipped with timers and cycle control features, allowing the operator to set the pressing time and cycle duration. This enables efficient operation and ensures consistent production output.

Safety Features

Cold press machines are equipped with safety features to protect the operator during operation. These can include emergency stop buttons, safety guards, and safety interlocks to prevent access to moving parts or the pressing area.

There are no reviews yet.