Here are some key features and aspects of a bamboo kulfi stick making machine:

Raw Material Feeding

The machine is designed to handle raw bamboo material, typically bamboo culms or poles, which serve as the source for the kulfi sticks. The bamboo culms are fed into the machine for further processing.

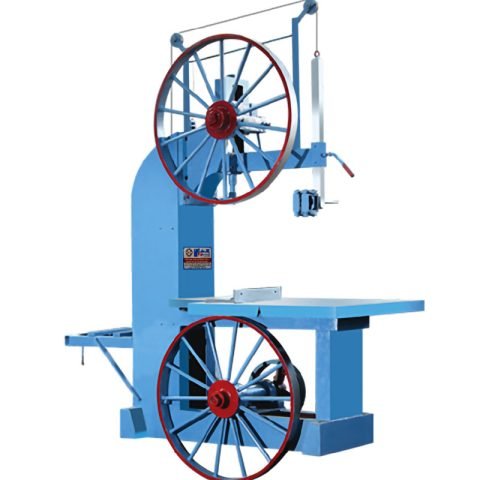

Cutting Mechanism

The bamboo kulfi stick making machine incorporates a cutting mechanism that cuts the bamboo culms into smaller sections, which will serve as individual kulfi sticks. The cutting mechanism may involve blades or saws specifically designed for bamboo processing.

Shaping and Polishing

After the bamboo culms are cut into sections, the machine may include additional processes to shape and polish the kulfi sticks. This can involve removing any rough edges, sanding the surfaces for smoothness, and shaping the ends to ensure a comfortable grip.

Sizing and Sorting

The machine can be equipped with mechanisms to ensure uniformity in the size and shape of the kulfi sticks. This may involve sorting the sticks based on their dimensions or weight and discarding any sticks that do not meet the desired criteria.

Speed and Efficiency

Bamboo kulfi stick making machines are designed for high-speed production and efficiency. They can produce a large number of sticks in a short period, significantly reducing manual labor and increasing productivity.

Quality Control

Some machines may have quality control mechanisms to check the integrity and quality of the kulfi sticks. This can involve inspections for cracks, splits, or other defects that may affect the usability of the sticks.

Safety Features

Bamboo kulfi stick making machines are equipped with safety features to ensure the safety of operators during operation. These may include safety guards, emergency stop buttons, and safety interlocks that prevent access to moving parts.

There are no reviews yet.