While there might not be a specific machine dedicated solely to kite stick making, the production process typically involves the following steps:

Raw Material Preparation

The machine operator prepares the raw materials for kite stick production. This often involves selecting suitable materials such as lightweight and durable rods made from materials like fiberglass, carbon fiber, or bamboo.

Cutting and Shaping

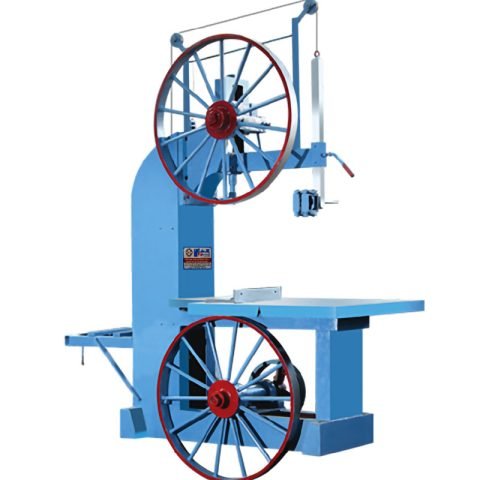

The raw materials are fed into the machine, which incorporates cutting and shaping mechanisms. The machine cuts the rods into desired lengths for kite sticks and may also shape them to the required thickness and profile. The cutting and shaping process can involve sawing, milling, or other cutting techniques depending on the chosen material.

Sanding and Finishing

Once the kite sticks are cut and shaped, the machine may have provisions for sanding and finishing. This step ensures that the sticks have a smooth surface and uniform thickness, allowing them to perform well during kite flying.

Quality Control

Some machines may include mechanisms for quality control, such as inspections to check for any defects, inconsistencies, or imperfections in the kite sticks. This ensures that only high-quality sticks are produced.

There are no reviews yet.