| Maximum width of bamboo strip | 25 MM |

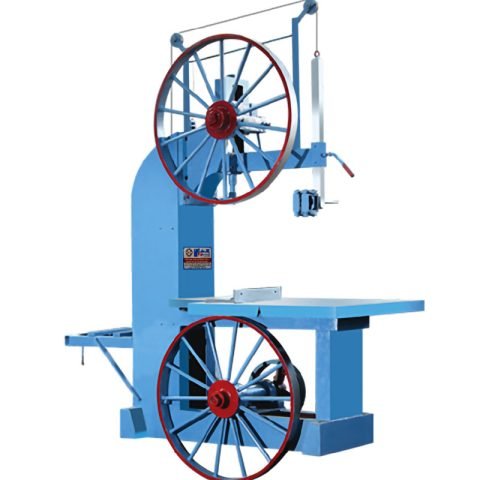

| Dimensions of the machine | 3’x2’x3 |

| Net weight, in kilograms | 450 kg |

| Maximum Thickness of slice | 2-3 MM Required:(1.8 MM MM) Without Knot |

| Power Consumption | 7H.P. (3 Phase) |

| Labour Requirement | Semi skilled |

| Carbide Cutter used Stick Making Cutter | 80 MM OD 25.4MM bore x 25 MM width |

Here are some key features and aspects of a bamboo round stick making machine:

Raw Material Preparation

The machine is designed to process raw bamboo poles or culms into round sticks. The operator typically feeds the bamboo poles into the machine for further processing.

Cutting and Sizing

The machine includes mechanisms for cutting the bamboo poles into desired lengths and sizing them into uniform diameters. This can be achieved using blades or other cutting tools that remove excess material and shape the bamboo into round sticks.

Shaping and Smoothing

After cutting, the bamboo sticks may undergo shaping and smoothing processes to achieve a more refined and uniform appearance. This can involve additional cutting, grinding, or sanding operations to remove any rough edges or imperfections.

Drying and Curing

Depending on the specific requirements of the bamboo sticks, the machine may include a drying or curing process. This helps to remove moisture from the bamboo and enhance its strength, durability, and stability.

Control System

Bamboo round stick making machines often feature a control system that allows operators to set parameters such as cutting lengths, diameters, and processing speeds. The control panel provides an interface for programming and monitoring the machine’s operation.

Safety Features

To ensure operator safety, bamboo round stick making machines are equipped with safety features such as emergency stop buttons, safety interlocks, and guards to prevent access to moving parts.

It’s important to note that the specific design and capabilities of bamboo round stick making machines may vary depending on the manufacturer and model. Some machines may have additional features or optional attachments for specific processing requirements. Bamboo round stick making machines automate the process of transforming raw bamboo poles into uniformly sized and shaped round sticks. These round sticks are commonly used in various applications such as furniture making, handicrafts, construction, and agricultural implements.

When using a bamboo round stick making machine, it’s important to follow safety guidelines and wear appropriate personal protective equipment (PPE) as recommended by the manufacturer. Regular maintenance and cleaning of the machine are essential to ensure optimal performance and longevity.

There are no reviews yet.